Since 1935, Embaré has been offering quality products, made with pure milk from the countryside, bringing nutrition to the table of thousands of families.

Guided by innovation and continuous research for improvement, we have built a strong culture that values our roots and our people, respects the environment and animal welfare, and strengthens our passion: to cultivate the best in people through food.

This solid foundation, combined with sustainable management, has allowed us to overcome daily challenges and expand our operations, fostering business growth and generating value for the entire ecosystem of which we are a part of.

This is only possible because we respect fundamental principles:

It's in everything we do, in our behaviors, in our processes and in our products. We work with a focus on continuous improvement and customer satisfaction.

We carry out sustainable management based on 3 pillars: financial, social and environmental. Our products follow strict quality and safety standards, which allows us to offer the best milk to our consumers.

Transparency is present in all our relationships. We always comply with the laws and commitments we have made.

We value our roots and each link in our chain. Collaborative work helps us keep the dairy universe in constant motion.

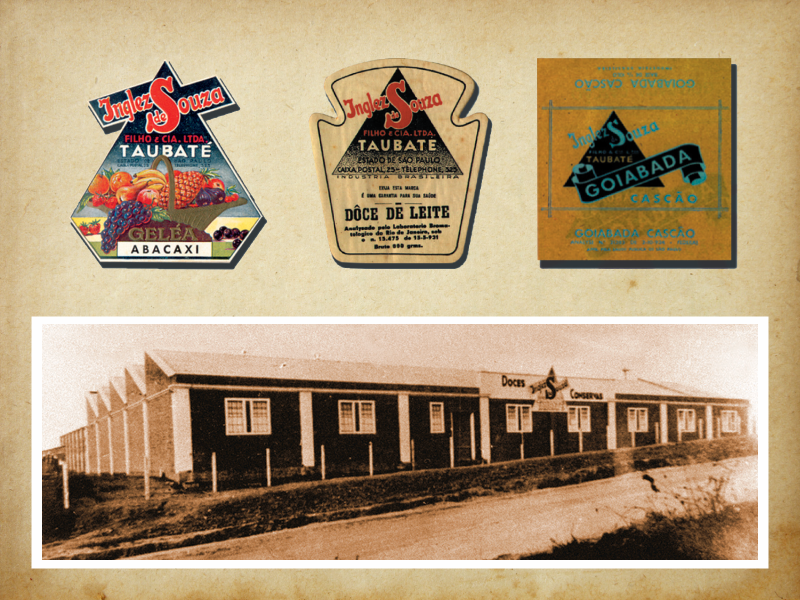

Founded on May 15, 1935, at Granja Embaré, in Taubaté (SP), the company “Inglez de Souza Filho & Cia Ltda” manufactured and sold milk and fruit jams, jellies, soups, tomato paste, in addition to of harvest fruits and vegetables.

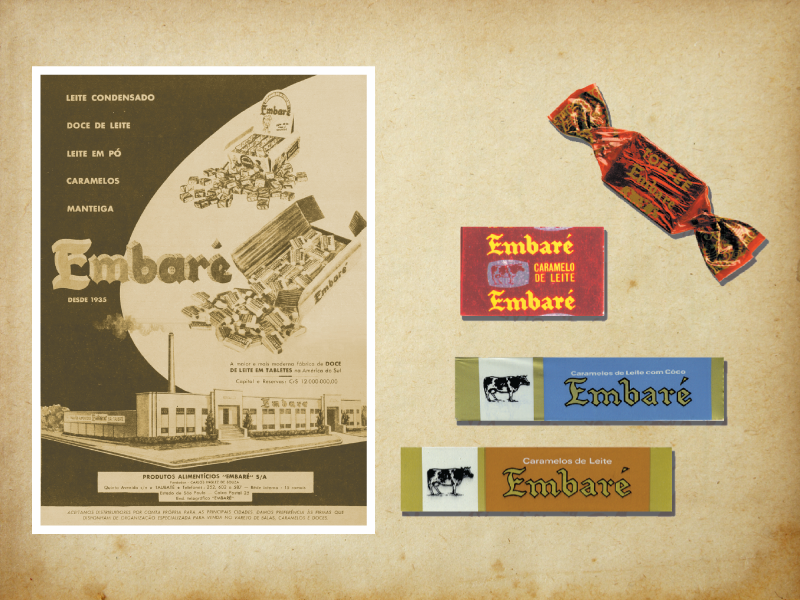

“Inglez de Souza Filho Ltda” changes its corporate name to “Produtos Alimentícios Embaré SA”. Start of production of the famous caramels.

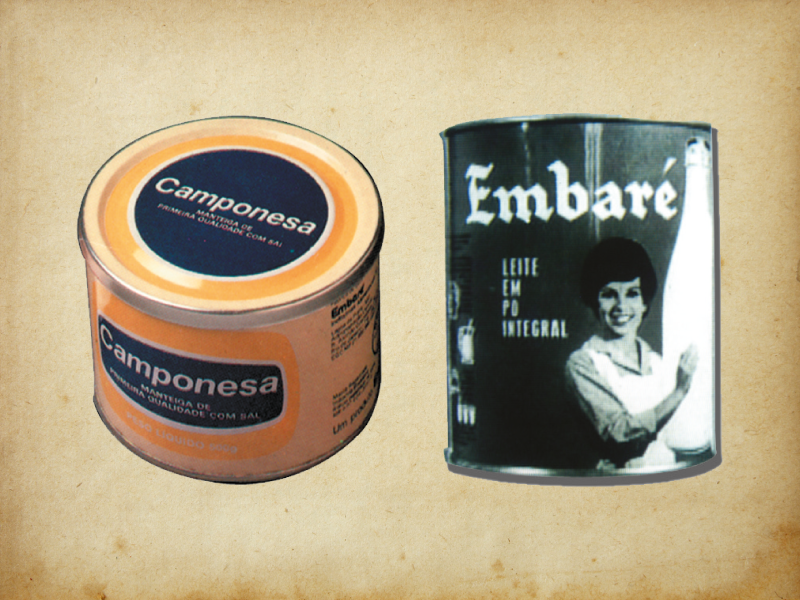

In Lagoa da Prata (MG), a group of ranchers created the company “Laticínios Lagoa da Prata Ltda”, for the production of butter and powdered milk under the brand name “Camponesa”. The company had a processing capacity of 10 liters of milk/day.

“Laticínios Lagoa da Prata Ltda” expands butter sales Camponesa to the North and Northeast states of the country and starts to produce industrial skimmed milk powder.

The current controllers of the company buy "Laticínios Lagoa da Prata" and become pioneers in developing the packaging of plastic bags for powdered milk.

The companies “Laticínios Lagoa da Prata Ltda” and “Produtos Alimentícios Embaré SA” merge, forming the current Embaré Indústrias Alimentícias SA

The industrial unit from Taubaté (SP) is transferred to Lagoa da Prata (MG), with the unification of industrial operations.

Embaré starts exporting its caramels to the foreign market.

From 1980 to 1985, a brief but important partnership was made with Kraft Inc., the largest American food company at the time.

With hard work, persistence and dedication of directors and employees, Embaré overcomes the financial and economic difficulties that occurred in Brazil in the early 1990s.

The company starts an expansion program, investing around 6 million in the modernization of equipment in the candy segment.

Inauguration of the Industrial Effluent Treatment Station – ETEI, in Lagoa da Prata.

Launching of new products such as condensed milk, cream, milky drinks under the Embarézinho brand, and pasty and bar milk candies. Company reaches the processing capacity of 1,7 million liters of milk per day.

Embaré is the first industry in Brazil to receive the FSSC 22000 certification, which guarantees the food safety of its entire product line. The certification has worldwide recognition and is granted to companies that meet all the necessary requirements for food production.

Expansion of the product line with the launch of UHT milks in whole, semi-skimmed and skimmed versions, and later the Low Lactose UHT milk.

Acquisition of a new industrial unit in Santo Antônio do Monte (MG), dedicated to the production of the cheese line Camponesa.

Launch of the cheese line Camponesa, with the items Minas Padrão, Minas Meia Cura, Mozzarella, Processed Cheeses and the innovative Queijo Fresco − the 1st boxed cheese in Brazil.

Total lease of the Quatrelati factory in Patrocínio (MG). The company starts to process 2,8 million liters of milk/day.

Embaré concludes a business combination with Betânia Lácteos, leader in UHT in the Northeast. With the association, the new group now has 9 factories, 13 distribution centers, with the capacity to process 4,8 million liters of milk per day, making it the 5th largest dairy industry in Brazil.

Click here to learn more

Click here to learn moreISO 14001 certification

The ABNT ISO 14001 Standard, which follows international rules, has as its main objective to ensure compliance with environmental management requirements and good production practices, so that the company meets its socioeconomic needs in accordance with the law and in balance with the protection of the environment. environment.

Click here to learn more

Click here to learn moreFSSC 22000 Certification

The FSSC 22000 standard (Food Safety System Certification) sets out the requirements for the production and placing on the market of products and foods that are safe for consumers. The FSSC 22000 standard integrates ISO 22000:2018 and ISO/TS 22002-1, is supported by the Confederation of EU Food Industries (CIAA) and approved by the Global Food Safety Initiative (GFSI).

Embaré's reverse logistics project, developed in partnership with Cleantech Polen, aims to reduce the environmental impacts generated by packaging and mitigate the emission of carbon (CO²) and other greenhouse gases in the atmosphere. After consumption, the packages that were placed on the market by Embaré are collected and destined for new production chains, fostering the Circular Economy through the investment and development of several recycling operators throughout Brazil. Access our sustainability report and check out more details on this initiative. CLICK HERE TO LEARN MORE

The industrial waste recycling program aims to provide adequate disposal of waste, reducing environmental impact as much as possible. Technically, it consists of reusing, recycling or landfilling the waste generated by the company. This conduct demonstrates the commitment to environmental responsibility and the NBR ISO 14001 management system.

Embaré invested in the physical structure of the Waste Center, benefiting the selective collection, storage and disposal of waste. More than 90% of solid waste generated is recycled, and more than 400 tons of recyclable material are donated to Ascalp – Association of Collectors of Lagoa da Prata. The rest of the non-recyclable waste is sent to companies specializing in the treatment of these materials. In this way, the company guarantees the correct destination of all the waste it produces.

The ETEI was built in 1997 and had its capacity increased in 2008. In 2016 the station underwent significant improvements in the technology of the treatment processes, with the aim of improving the efficiency of the system, improving the quality of the water released into the receiving body and produce biofertilizer from solid waste. The effluents are submitted to a physical and biological treatment in anaerobic lagoons and stabilization lagoons. Already treated and analyzed in an exclusive laboratory, the water is released into the receiving body.

In the Clean Development Mechanism (CDM) project developed by Embaré, part of the biogas − composed mainly of methane, generated in the Industrial Effluent Treatment Station (ETEI) − is driven to a generator and, from its combustion, is transformed in electric energy, used for the maintenance of the ETEI; the other part returns to the factory and is used as fuel to generate steam in the boiler. The burning of biogas provides the elimination of 600 tons of biomass per month, contributing to the reduction of the greenhouse effect and engaging in the policy of using renewable energy sources.

Embaré has, since 2014, a biomass boiler in its factory. It occupies an area of 1.615m² and has a steam production capacity greater than the sum of the capacity of the three previous boilers. The gases from the burning of biomass are free of substances composed of heavy metals; in addition, the boiler has even more advanced safety features, electronically controlled, with noise mufflers and thermal and acoustic insulation, preventing heat and noise from interfering in the internal and external environment of the factoryapprox.

Embaré periodically monitors gaseous emissions from boiler chimneys, ensuring levels of sulfur, carbon monoxide and nitrogen oxides are well below the limits required by Brazilian legislation.

Embaré has developed a system for the recovery of evaporated water in the milk concentration and drying process. The system is equipped with conductivity meters and automatic valves that direct the water to processes that require low hardness water. This system reduces the amount of water collected in artesian wells and reduces the use of chemical products for water treatment, also reducing the impact on the environment. Another Embaré commitment is to the rational use of water resources. In milk production, the company consumes only 1,4 liters of water for each liter of industrialized milk, while the national average is 3 to 4 liters of water. To reach this percentage, several measures were adopted over the last few years, such as installing a level meter in the milk reception bay and reusing condensed water to generate steam in the boiler.

Embaré has a project to recover 80% of the condensed water from the steam consumption points. The recovered water is used in the boilers at a temperature of 80°C, reducing fuel consumption and reducing the consumption of potable water.

Embaré makes a rigorous selection of packaging suppliers. Everyone who supplies the paper packaging is FSC certified and undergoes annual audits carried out by the Integrated Management System area. In addition, the brand's carton products Camponesa they also have both the cap and the plastic that make up the protective layers of the packaging from sugarcane. The so-called “green plastic”, polyethylene produced from ethanol, is a source of renewable raw material. Even though it is not biodegradable, the material is more beneficial to the environment than conventional petroleum-derived plastic. This is because it reduces the emission of greenhouse gases into the atmosphere, which cause global warming.

With the production of dairy products, Embaré Indústrias Alimentícias SA has an integrated Quality and Food Safety policy established, disseminated to all its employees and publicly disclosed through boards, institutional website, internal communication vehicles and other vehicles that are made needed, depending on the occasion.

Embaré Indústrias Alimentícias SA considers the Integrated Management of Quality and Food Safety, committing itself to:

Eeducate and raise awareness among employees so that they can carry out their tasks, ensuring the quality and safety of food.

MContinuously improve the Food Safety Management System, improving food quality and safety.

BUse a good relationship with stakeholders, reconciling expectations and fulfilling the commitments assumed.

Acomply with applicable legal requirements and standards.

Rand pass on to suppliers and service providers the procedures and requirements of the Food Safety Management System.

Edeliver safe and quality products satisfying and meeting customer requirements.

Embaré Indústrias Alimentícias SA, with the production of dairy products and confectionery, has an integrated policy for the Environment, Quality and Food Safety established, disseminated to all its employees and publicly disclosed through boards, institutional website, internal communication vehicles and other vehicles that are necessary, depending on the occasion.

Embaré Indústrias Alimentícias SA, with coverage in all continents, considers the Integrated Management of the Environment, Quality and Food Safety, committing itself to:

Eeducate and raise awareness among employees, so as to reduce the environmental impact of their activities and carry out their tasks, ensuring the quality and safety of food.

MContinuously improve the Integrated Management System, improving environmental performance, quality and food safety.

BUse a good relationship with stakeholders, reconciling expectations, fulfilling the commitments assumed, protecting the environment and preventing pollution.

Atend to the legal requirements and applicable standards, acting in a sustainable and rational way.

Rand pass on to suppliers and service providers the procedures and requirements of the Integrated Management System.

Edeliver safe and quality products, satisfying and meeting customer requirements.

Embaré Indústrias Alimentícias SA, with the production of dairy products and confectionery, has an established Halal Policy, disseminated to all its employees and publicly disclosed through boards, institutional website, internal communication vehicles and other vehicles that are necessary, depending on of the occasion.

Embaré Indústrias Alimentícias SA, with coverage in all continents, considers the Halal Guarantee System (SGH), committing itself to:

Hhonor the commitments undertaken in fulfilling the requirements set out in the Holy Qur'an, Islamic Jurisprudence and relevant legislation;

Aensure understanding of the Halal Policy among employees;

Lrelease resources necessary for maintaining the SGH, in order to guarantee the Halal status of certified products;

Aensure continuous improvement of processes and products, seeking to improve the quality and safety of products offered to the Muslim public;

Llead actions with suppliers and stakeholders, reconciling expectations and commitments assumed.

We seek to contribute to the quality of life and social well-being and generate a positive impact on communities in the regions where we operate. We work sustainably through ethical, transparent and responsible conduct, multiplying our values through the triad: employees, family members and society.

Food Donations

Through the Cultivando o Bem Project, we help more than 100 philanthropic institutions, which have initiatives aimed at the sustainable development of local communities in several municipalities. With this movement, we help these organizations bring hope to those in need.

Embaré's Choir Foundation

With its activities started in 2001, the Embaré's Choir Foundation includes among the participants company employees, their families and community members.

Hilde Schmidt Cultural Center

Created to meet the company's cultural demands, lectures, shows, concerts and film screenings, the Hilde Schmidt Cultural Center, also provided to the community, is a space for holding events for popular and governmental segments of the municipality.

Embaré Employees Recreational Association – ARCE

Among the projects that benefit Embaré employees, the most prominent is the Associação Recreativa dos Collaborators da Embaré – ARCE, founded in 1982. The realization of this socio-sports project provides Embaré employees and their families with a place for socializing and practices sports.

Continuous Improvement of Milk Quality

To assist the producer in the continuous improvement of his product, Embaré provides technical training and guidance visits, with highly qualified consultants who help in the implementation of processes and management to guarantee well-being, animal health and milk quality.

Educampo Project

Educampo is an innovative project that has benefited thousands of producers, through planned actions that make dairy farming increasingly efficient and profitable. Developed in partnership with SEBRAE/MG, it aims to provide technical and managerial training to our partners. The project provides the producer with an entrepreneurial vision of his business, with a focus on economic results.

Model Farm

Embaré, in partnership with QCONZ – Latin America (a New Zealand multinational, world leader in projects and consultancy for the dairy sector), developed a Good Agricultural Practices Program, which involves: animal welfare, management, infrastructure and quality of the milk.

The program has simple tools and methods that are easily applied on farms.

The partner producers participating in the project receive follow-up through visits and diagnosis, and are instructed to use the system of good agricultural practices on the farm and improve the level of quality at all stages of production.

The management system, implemented effectively, aims to make the processes employed more sustainable and efficient, putting the company on the path to standardization and quality.

Input Purchase Program

Embaré supports its rural producers, searching the market for the best opportunities to buy food for production. Everything to offer better conditions of purchase and maximization of profits, passing on to suppliers the inputs at cost price, in addition to making available and enabling the adoption of techniques and strategies for stocking the items purchased.

Various inputs are available, ranging from fertilizers for the production of roughage and grains to concentrates used in the formulation of diets.

An opportunity for the small producer to have the same purchasing power as a large producer.

More Genetics Project

Embaré, in partnership with its rural producers, created the Mais Genetic Project. This initiative aims to encourage the genetic improvement of its partners' herds, through the Fixed Time IVF Embryo Transfer (In Vitro Fertilization) technique.

This technology makes it possible to identify and use more qualified animals for reproduction, ensuring the birth of calves with high genetic value and the genetic improvement of the herd with assertiveness.

Through these genetic improvement instruments, producers can improve the productivity of their herd, adding value to their production and with a good economic return in the dairy activity.

Auctions

Embaré holds animal auctions. The initiative aims to create a link between the producer who has a surplus of animals and the producer who has demand.

At the opportunity, the producer can purchase the animals in up to 10 interest-free installments, and all the animals purchased produce milk before the first installment. Therefore, it is possible that the production itself helps pay for the purchase made.

This practice is advantageous for the producer both in terms of more competitive prices and the optimization of time in the search for new animals.

SAC: (0800) 707 5533

Email: [email protected]

SAC: (0800) 707 5533

Email: [email protected]

Media Relation

:

(31) 3279-2133

[email protected]